Reading the VACUUM gauge:

Reading the VACUUM gauge:

Many engine tuners optain state-of-the-art diagnostic equipment and have forgotten one of the simplest,

as well as most accurate tuning tools ...In most cases you can effectively monitor and tune your

car's fuel and timing systems using a quality vacuum gauge (like the

one we provide with our DIY systems).

First a few basics:

NOTE: connection to EFI cars is best done "Tee'd" into the

source line from the heater system. Other vacuum connections can

effect the idle speed as well

as information that the ECM needs to see.

- You must check and if necessary adjust the

ignition timing, valve clearance, sparck plug gap and contact angle of

the contact points.

- After the adjustments are made, you MUST

RESET your idle speed setting. You must do this to have a standard or

baseline to compare with.

- If you fine tune the LPG system small adjustments are best, and in fact

"optimum" settings on the vacuum gauge (highest reading)

is usually the maximum power. The mixture than is a little richer than it

stricktly needs to be. In other words, after the highest

reading is reached, the best setting (depending on engine) is to set

mixture screws back "lean" approximately 1/16 to 1/4 turn.

- If your system uses an ECOmax, you get the the best milage

when

the vacuum read out will be 5 upto 10 degrees lower. (For

more information see the instruction manual.)

What does the gauge tell you?

Let's see .... It can help you find errors in:

Incorrect mixture, a vacuum leak, leaking power valve, and more

...

When I was young, I was told to

effectively tune an engine with just the vacuum gauge and a timing

light. Once the education and practice is there, it is a very effective technique. It

takes some patience, but the knowledge of how your engine behaves to tuning changes is

worth it.

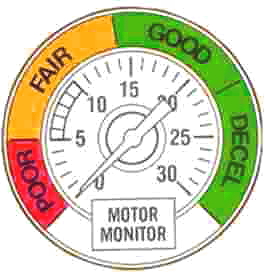

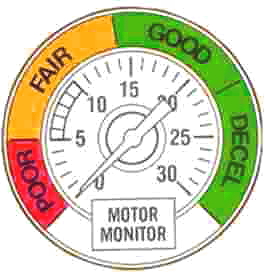

Detailed Vacuum gauge needle readings explained below (images at

right):

| Steady

needle |

Normal reading

(usually 17-22" Hg. in stock engines)

Race engines vary "a lot" and in most cases will be considerably less.

|

| Intermittent

fluctuation at idle |

Ignition miss,

sticking valves, lifter bleeding off (hydraulic), or just a BIG camshaft

|

| Low, though

steady reading |

Late timing,

low compression, sticking throttle valve, carb or manifold vacuum leak (remember most fast engines with a big cam and a tight centerline and

high overlap will be naturally low ... you must decide your baseline vacuum reading)

|

| Drifting

needle |

Improper carb

setting or minor vacuum leak

|

| Fluctuating

needle as RPM increases |

Ignition miss,

blown head gasket, leaking valve or weak or broken valve spring

|

| Steady, but

needle drops regularly |

Burnt valve or

incorrect valve setting (too tight), "needle will

fall when bad valve operates"

|

| Gradual

drop at idle |

Clogged

exhaust, excessive backpressure

|

| Excessive

vibration that steadies as RPM increases |

Worn valve

guides

|

|

Be aware!

some gauges turn clockwise some anti clock wise

Normal: (stock

engine)

Clogged exhaust:

Blown head

gasket:

Incorrect

valve timing:

Worn out valve

guides:

Mixture adjustment

needed:

Sticking valves:

Burnt or

leaking valves:

|

|

Reading the VACUUM gauge:

Reading the VACUUM gauge: